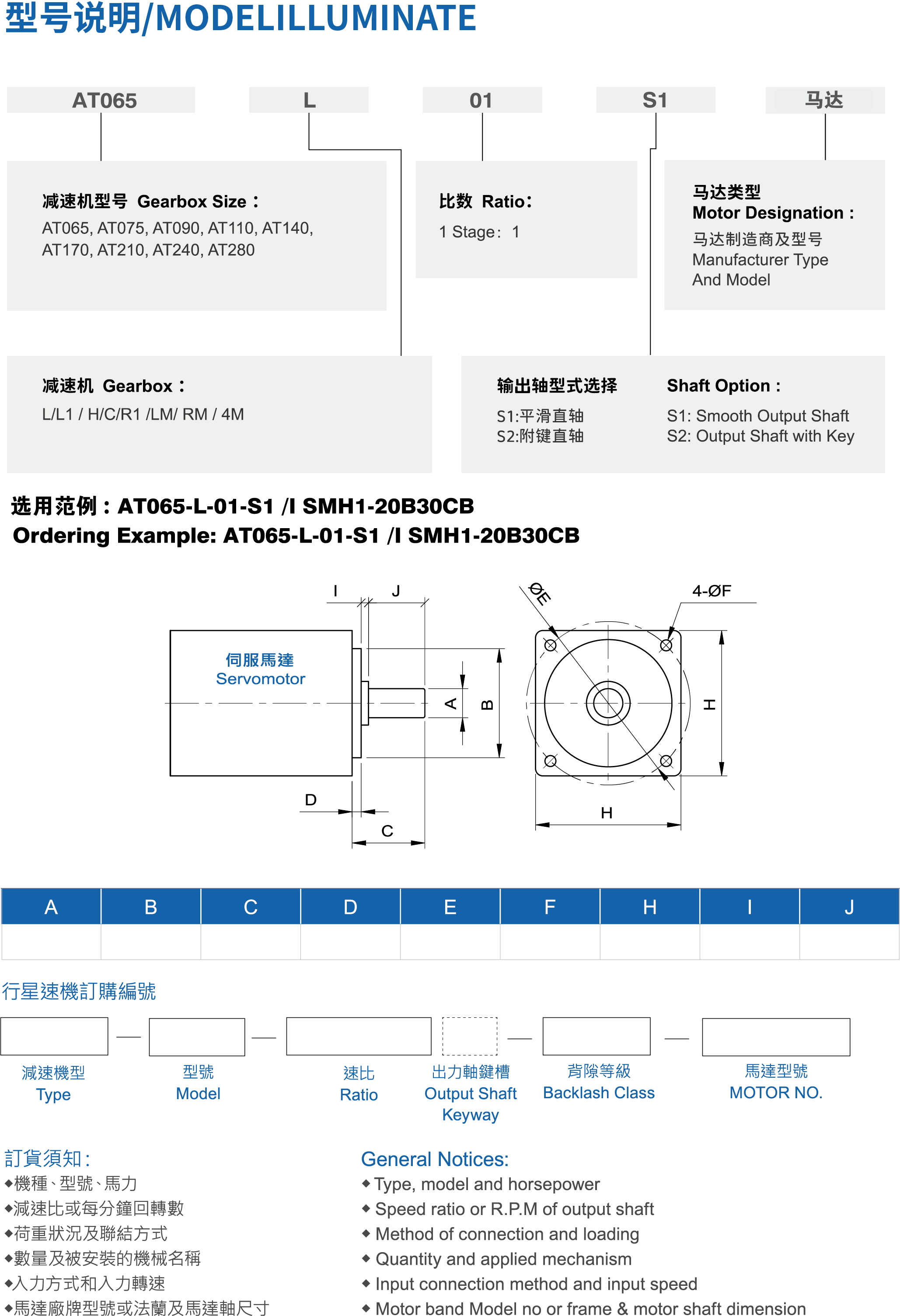

AT-FL1

产品特点:使用Gleason参数齿轮加工设备加工研磨等级的螺旋伞齿轮,确保低背隙、低噪音。背隙最小可达2弧分以内。多重精密加工表面易于组装,适用于任意安装方向。入出力轴的设计可以适用于各种工业上应用的需求。高精密研磨的蜗线伞齿轮组结合最佳化设计的行星式齿轮组可以达到500:1的减速比。

产品介绍:输入端与马达的连结操用筒夹式的锁,紧机横,并经动平衡分析,以确保在高输入转速下结合介面的同心度和平衡度,及零背隙的动力传递。一体式齿箱本体确保最大刚性与耐触性。结构繁凑,富有刚性的设计保证了在小体积,重量轻的情沉下能够达到最高扭矩及较大的减速比。免保养无须更换润滑油,运转寿命长。

参数表

| 规格Model No. | 节数 Stage | 比数A Ratio^ | AT065FL AT065FL1 AT065FH AT065FC AT065FR1 | AT075FL AT075FL1 AT075FH AT075FC AT075FR1 | ATO90FL ATO90FL1 ATO90FH AT090FC ATO90FR1 | AT110FL AT110FL1 AT110FH AT110FC AT110FR1 | AT140FL AT140FL1 AT140FH AT140FC AT140FR1 | AT170FL AT170FL1 AT170FH AT170FC AT170FR1 | AT210FL AT210FL1 AT210FH AT210FC AT210FR1 | AT240FL AT240FL1 AT240FH AT240FC AT240FR1 | AT280FL AT280FL1 AT280FH AT280FC AT280FR1 | |

| 额定输出力矩T2N Nominal Output Torque T2N | Nm | 1 | 1 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 |

| 1.5 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 | |||

| 2 | 24 | 42 | 68 | 150 | 330 | 544 | 1220 | 2010 | 3050 | |||

| 3 | 18 | 33 | 54 | 120 | 270 | 450 | 1020 | 1650 | 2850 | |||

| 4 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 2300 | |||

| 5 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 2 | 7 | 12 | 12 | 33 | 91 | 91 | 91 | 195 | 358 | 358 | ||

| 10 | 24 | 28 | 68 | 150 | 208 | 208 | 430 | 846 | 846 | |||

| 15 | 18 | 33 | 54 | 120 | 270 | 312 | 645 | 1269 | 1269 | |||

| 20 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 1692 | |||

| 25 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 35 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 50 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 3 | 75 | – | – | – | 120 | 210 | 312 | 585 | 1269 | 1269 | ||

| 100 | – | – | – | 100 | 224 | 376 | 780 | 1410 | 1692 | |||

| 125 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 150 | – | – | – | 120 | 135 | 312 | 390 | 975 | 975 | |||

| 200 | – | – | – | 100 | 180 | 376 | 520 | 1300 | 1300 | |||

| 250 | – | – | – | 85 | 196 | 320 | 650 | 1210 | 1625 | |||

| 350 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 1790 | |||

| 500 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 最大加速力矩T2B Max.Acceleration Torque T2B | Nm | 1.2.3 | 1~500 | 1.5 倍额定输出力矩 1.5 times ofNominal Output Torque | ||||||||

| 最大加速输入转速n1B Max. Acceleration Input Speed n1B | rpm | 1 | 1~5 | 7500 | 6500 | 5500 | 4500 | 3500 | 3000 | 2200 | 2000 | 1700 |

| 2 | 7~50 | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | 4800 | 3600 | 3600 | ||

| 3 | 75~500 | – | – | – | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | ||

| 背隙 Standard Backlash | arcmin | 1 | 1~5 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 7~50 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| 3 | 75~500 | – | – | – | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| 容许径向力 F2rB Max. Radial Load F2rB 输出轴 d2 Output d2 | N | 1.2.3 | 1~500 | 900 | 1100 | 1700 | 2700 | 4800 | 6600 | 11500 | 16000 | 18000 |

| 容许轴向力 F2aB Max. Axial Load F2aB 输出轴 d2 Output d2 | N | 1.2.3 | 1~500 | 450 | 550 | 850 | 1350 | 2400 | 3300 | 5750 | 8500 | 9000 |

| 使用寿命 Service Life | hr | 1.2.3 | 1~500 | 20000 | ||||||||

| 效率η Efficiency η | % | 1 | 1~5 | ≥98% | ||||||||

| 2.3 | 7~500 | ≥94% | ||||||||||

| 使用温度 Operating Temp | ℃ | 1.2.3 | 1~500 | (-)10℃~90℃ | ||||||||

| 润滑 Lubrication | 1~500 | 合成润滑油脂 Syntheticlubrication oils | ||||||||||

| 噪音值(n1=1500rpm,无负载) Noise Level(n,= 1500rpm, No Load) | dB (A) | 1.2.3 | ≤71 | ≤72 | ≤76 | ≤77 | ≤78 | ≤79 | ≤81 | ≤83 | ≤84 | |

订购须知 / 客户填写